RELATED PRODUCT BRANDS

EXPLORE OTHER PROMACH BUSINESS LINES

EXPLORE OTHER PROMACH BUSINESS LINES

ProMach offers one of the most robust lineups of filling technologies in the world, with a complete range of solutions that can fill liquid and viscous food, beverage, dairy, pharmaceutical, personal care, chemical, household, and industrial goods products into a variety of rigid containers. With our broad range of filling capabilities, we can partner with customers to help them choose the best solution for their unique application needs each and every time.

ProMach is your partner from start to finish. Our product brands are grouped into distinct business lines that make the most sense to our customers, covering every function of the production line: Filling, Bottling & Capping, Decorative Labeling, Flexibles & Trays, Pharma, Handling & Sterilizing, Labeling & Coding, Robotics & End of Line, and Systems & Integration.

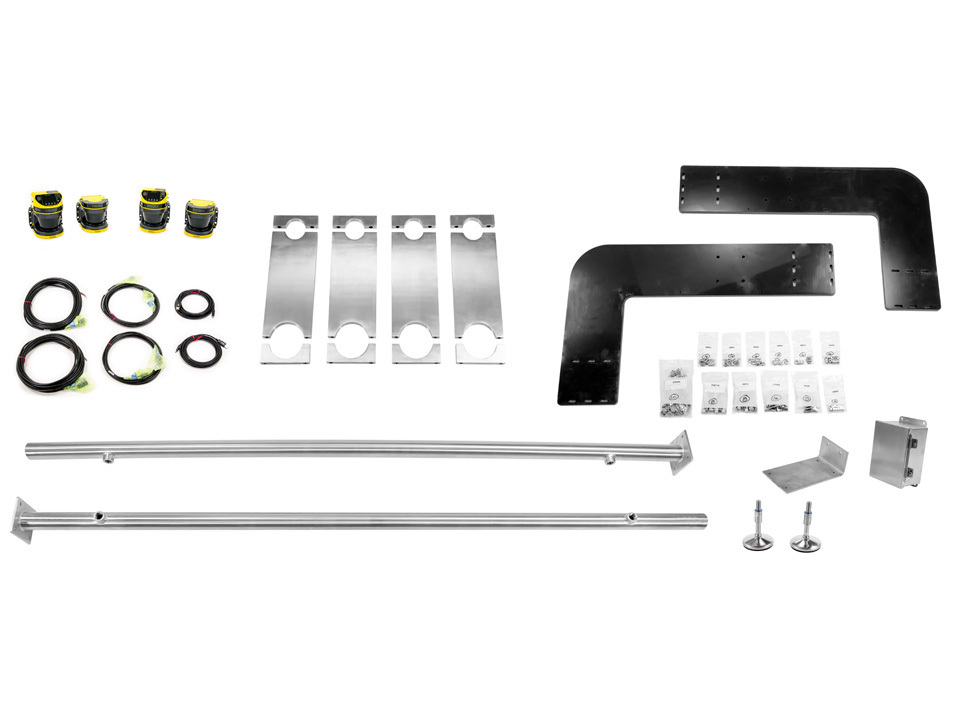

learn moreSure-Seal High Performance Filling Valve Features & Benefits

- One-piece compression molded urethane valve tip with fused silicone valve seal eliminates black o-ring in current valve tips – reduces maintenance expense and hassles

- Under typical production conditions the new one-piece urethane silicone valve tips will require replacement every one-to-two years (minimum 4.5 million cycles) – reduces maintenance labor and expenseCurrent valve tip o-rings must be replaced monthly to prevent filling quality issues, including valve leaks and drips

- Current filling valves featuring the black o-ring in the valve tip are held together by the black o-ring, and failure of an o-ring can cause valves to come apart and detach from the filling bowlThis makes monthly replacement of the black o-rings a "must do" task on every preventative maintenance schedule

- New low friction inner o-seal reduces bottle topload – reduces scrap, increases uptime and shortens commissioning process for lightweight bottles

- New valve design provides cam-actuated CIP cleaning capabilities – valves can automatically opened and closed during CIP cycling, providing enhanced cleaning-in-place via turbulent flowOptional automated CIP system includes rapid drain pan, integrated CIP fluid collection holding tank and dual cam system for valve actuation

- Sure-Seal valves feature a new fast-snap vent tube locking clip with a failsafe design – vent tube locking clip cannot fall into filling zone and Sure-Seal valves cannot be removed until clip is removed

- Sure-Seal valves can be removed, disassembled, reassembled and installed without the use of tools – simplifies valve replacement and cleaning out-of-place